It supports for mild steel and high-alloy steel, and may be used in deep-hole, non-through-hole and sintering parts.

"What's the Gas Nitrocarburizing"

Many kinds of steels, improving wear resistance, fatigue strength, corrosion resistance.

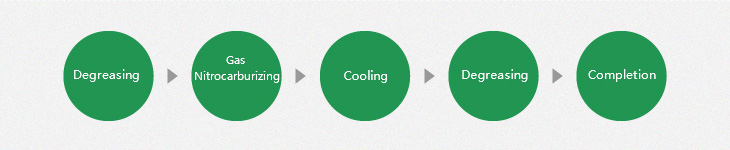

Gas Nitrocarburizing treatment refers to a kind of treatment process that heats the products in furnace to 530~600℃ in the mixed gas environment of NH, N, and CO, uses N component decomposed from NH for nitridation, C component decomposed from CO for leaching carbon, and 5~20μm or so Iron nitride to generate the coating of compound layer on the product surface.

The resulting compound layer is meticulous with high hardness and proper toughness, which is mainly helpful to improve the wear resistance of the component surface. In addition, the surface is covered by the compound layer, and the corrosion resistance is also improved.

In addition, a solid-solution nitrogen diffusion layer is formed from the bottom of the compound layer to the inner part of 0.5mm after Gas Nitrocarburizing, so it can improve the fatigue strength.

The surface hardness obtained is about HV400~600 in normal steel. According to the type of steel, the maximum hardness of HV900 can be obtained.

In term of steel types, as shown in gas nitridation (Pure nitridation), there is no need to be nitriding steel. It widely supports mild steel, alloy steel, cast iron and sintered steel (However, it does not apply to stainless steel with non-dynamic coating).

In addition, because the treatment under transformation temperature is not accompanied by quenching, such advantages as little deformation, clean and beautiful appearance, clean process, easiness in automation operation, etc. are obtained after the heat treatment.

Furthermore, for the pre-treatment of Gas Nitrocarburizing for sintered parts, the Company can also support sealing treatment with steam treatment furnace.

Besides, the Company is actively committed to the use of hydrogen sensors for potential nitridation control of Gas Nitrocarburizing.

One case of nitridation treatment

1. Applicable types of steel: Mild steel, carbon steel, alloy steel, cast iron, sintered steel materials (Except for stainless steel)

2. It also supports deep-hole, non-through-hole, micro-pore products, etc., and the shapes that cannot be used due to salt blockage in Isonite Treatment.

3. A clean and smooth appearance can be obtained because it is difficult to attach oxide skin on the surface and the roughness is controlled to a minimum.

4. Take use of compound layer with high hardness and low friction coefficient to improve wear resistance.

5. Take use of the residual compressive stress on the surface and the formation of nitrogen solid solution in the diffusion layer to prevent the translocation and improve the fatigue strength.

6. Take use of the properties of high temperature softness of compound layer to improve heat resistance.

7. The surface is covered with a compound layer of non-metallic properties, thus improving its corrosion resistance

660W×1,230L×720H

760W×1230L×720H

Mechanical components centering on two-wheel and four-wheel vehicles

(plunger, cylinder, drum clutch, plate damper spring, main separators etc.)

Other general mechanical components, home appliance components, etc.

『 The above is quoted from Hamamatsu Netsushori Co., Ltd 』