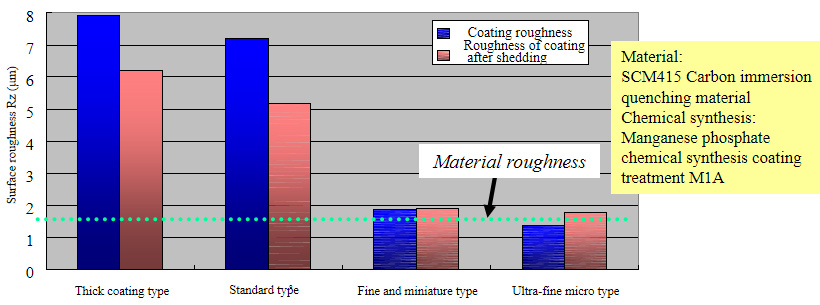

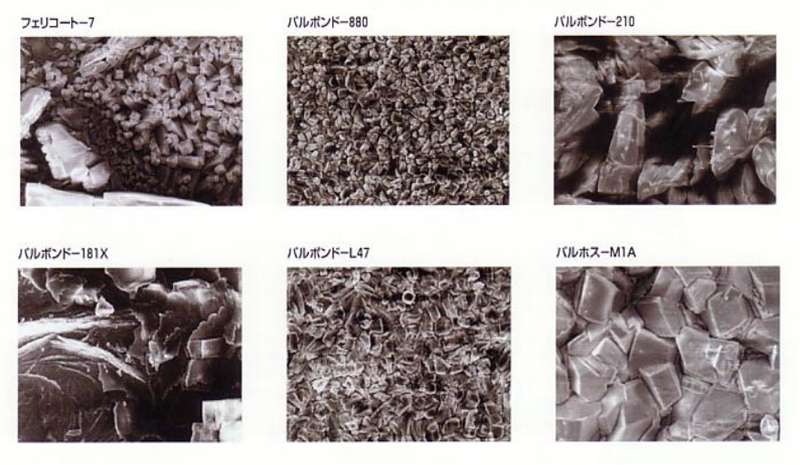

● A uniform surface roughness state that can't be obtained by shot blasting can be obtained.

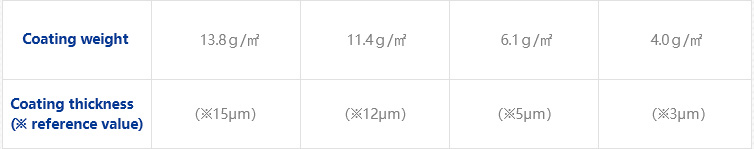

● There is little change in the size and weight of articles before and after the treatment.

● It is difficult to produce grinding powder, injection molding powder and other foreign matter adhesion which may be caused by physical methods.

● It is also suitable for large objects with complex shapes, which are difficult to achieve by physical methods.

● It can be applied to objects (sheet, etc.) that are weak in strength, as they are achieved by physical methods. In addition, The treatment temperature is also below 100 ℃, so the material will not produce a physical change.

● By selecting the appropriate surface treatment (post-treatment), a more secure binding force can be obtained.

● It is difficult to see the deterioration of the binding force which may be caused by physical methods.

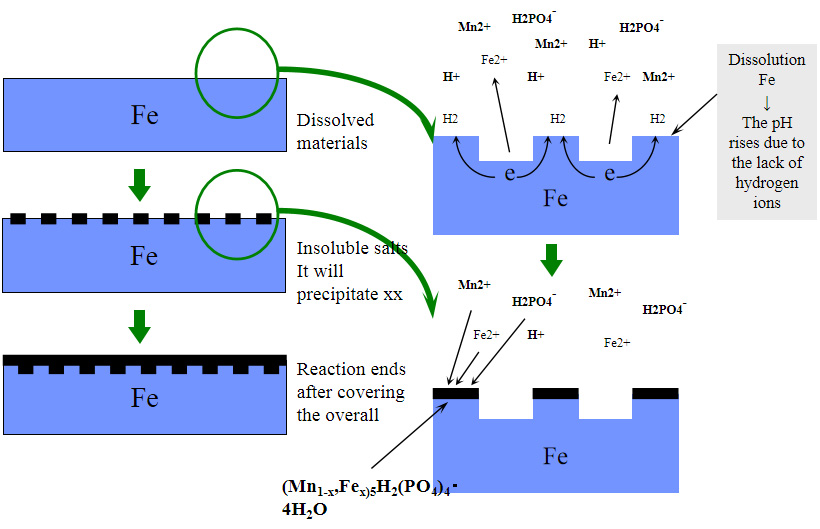

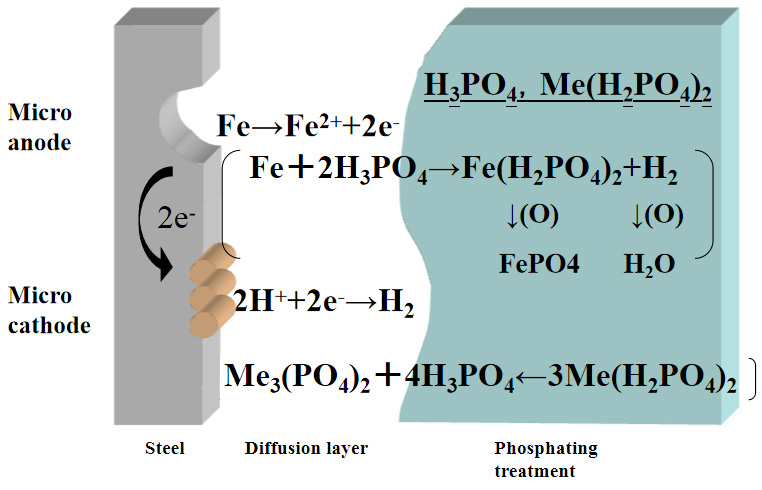

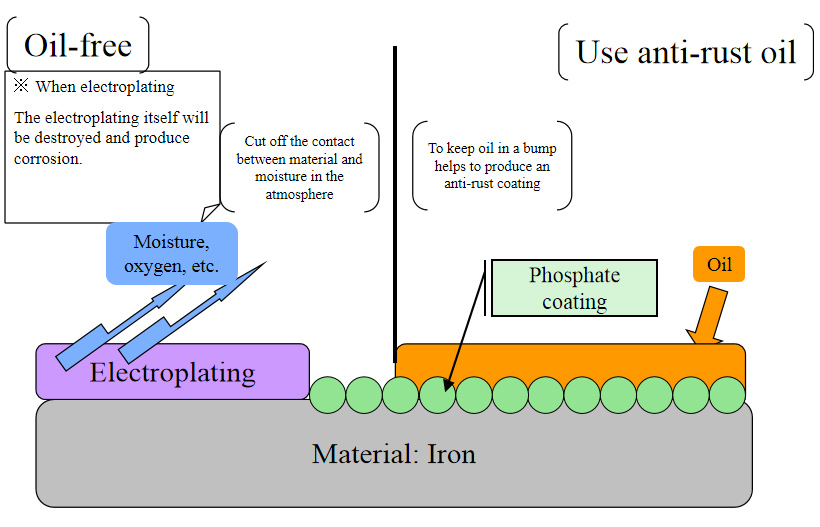

● The corrosion reaction is produced by the combination of anodic reaction (oxidation reaction) and cathodic reaction (reduction reaction).

● The corrosion product mainly is the insoluble metal hydrated oxide produced after the rise of pH near to the metal surface due to cathodic reaction.

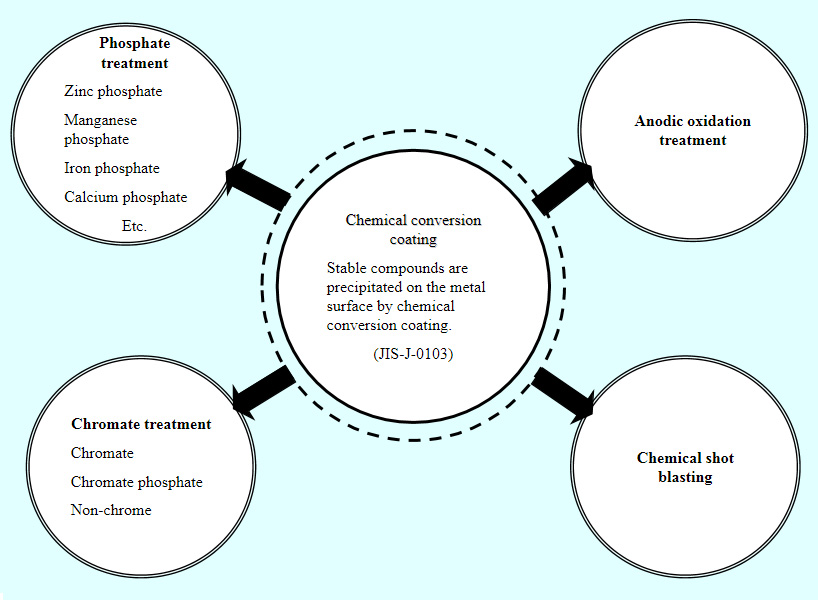

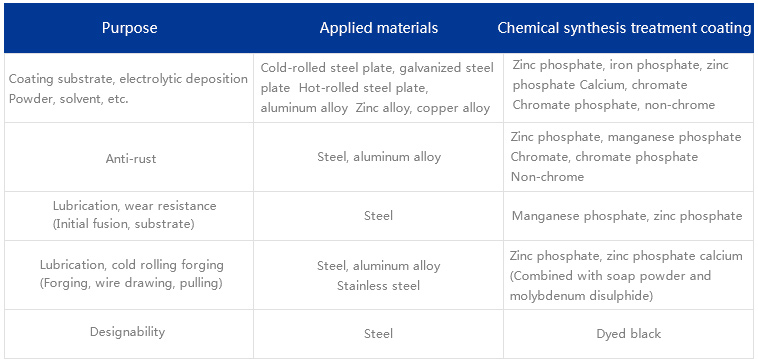

● The chemical synthesis treatment is carried out by using the above-mentioned reaction to artificially combine the minimal solubility and appropriate oxidant (Ex: NO2, NO3) with the cation (Ex: Zn, Mn, Ni) or anion (Ex: PO4).

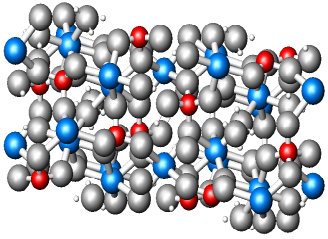

Molecular formula: (Mn1-x,Fex)₅H₂(PO₄)₄・4H₂O

Crystal structure: Monoclinic system

Hardness:5 (Moh's hardness)

Heat resistance:370℃ (differential thermal analysis)

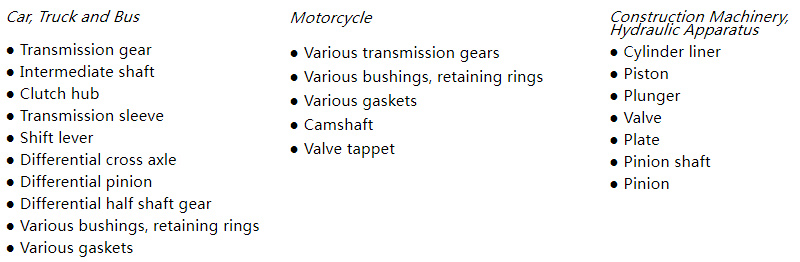

→ Sliding parts (Gear, bearing, cam, etc.)

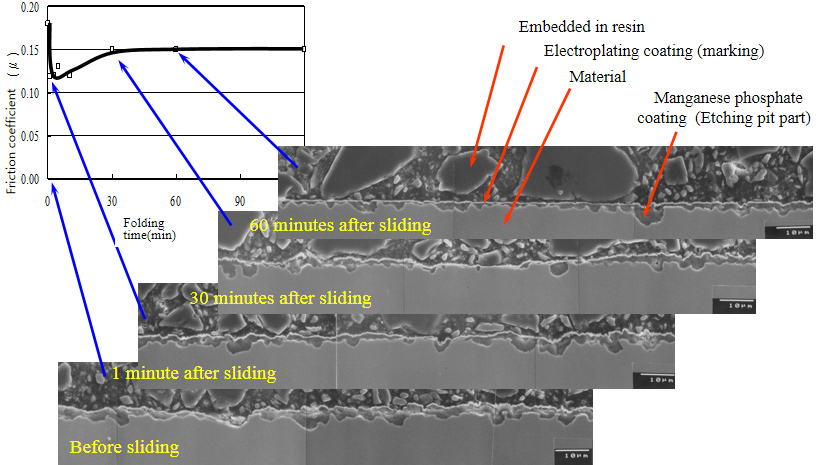

Because of its excellent affinity with grease, lubricants have a high retention capacity.

Because it is an inorganic coating with good associativity, it will absorb stress and prevent direct contact between metals (charring).

By covering the defects and inhomogeneity of the sliding surface, the sliding surface will be fused rapidly.

It has the effect of reducing the noise of the sliding part and improving the corrosion resistance of the sliding part.