Improve sliding characteristics (reduce friction coefficient)

Lubrication under high load and initial fusion with oil lubrication (no test run)

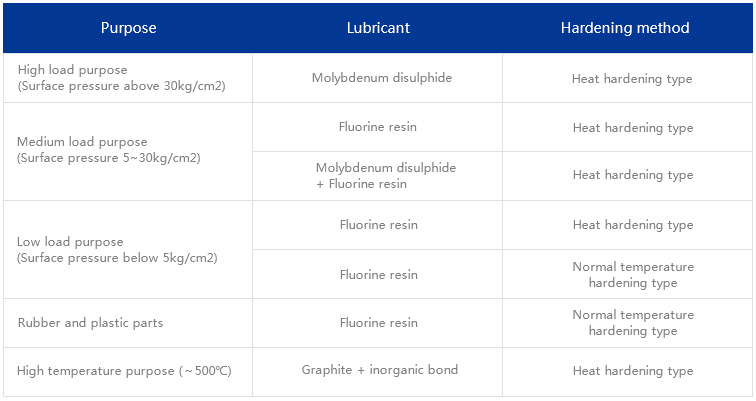

It can solve the problems of lubrication, drying, adhesion, dirt and so on (without oil) under the conditions of high temperature, low temperature, vacuum, ultra-high pressure, radiation resistance and so on, which cannot be lubricated by oil / lubricating grease, etc.

It can treat a variety of metals and alloys, resins, rubber and other materials.

Even a thin coating can make the most of it.

It can be partially treated.

It can make flexible use of electronic properties (conductive, insulating)

It can also support non-lubricating (prevent slippage) features

It can also be given non-adhesion, waterproofing, anti-fouling, silence, drug resistance and other properties.

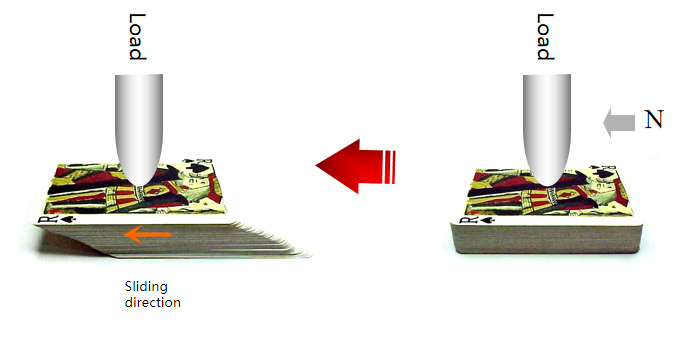

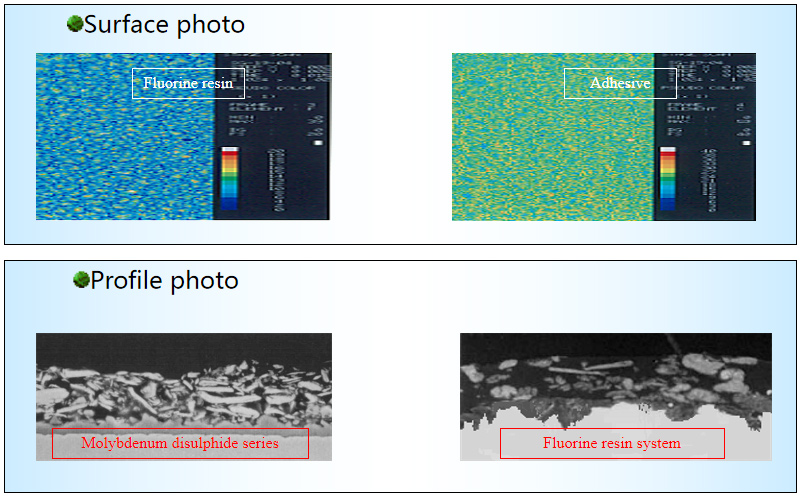

In the pattern construction diagram which is easy to understand the construction state of lubricant, their sizes are different.

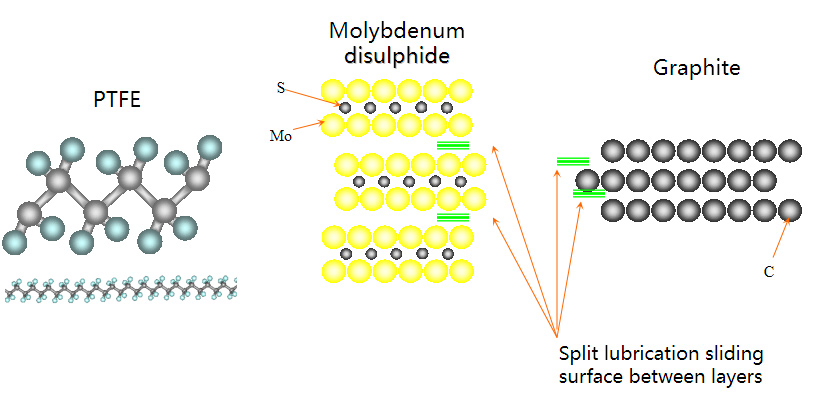

Solid lubricants, such as molybdenum disulphide and graphite, are lubricated by sliding between layers and splitting between molecules. The pattern diagram briefly illustrates the slide.

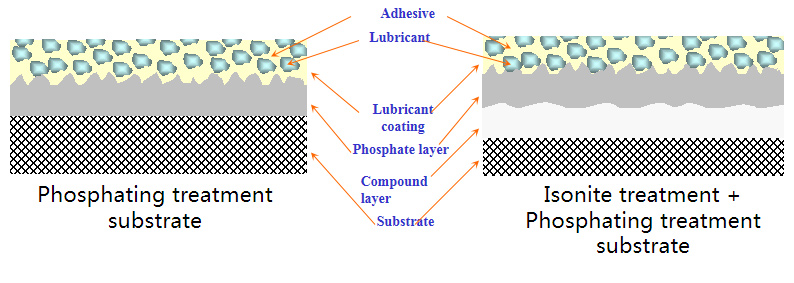

The thickness of the compound layer treated by isonite treatment is not the size added to the substrate size.

There is also a method of isonite treatment + shot blasting finishing substrate.

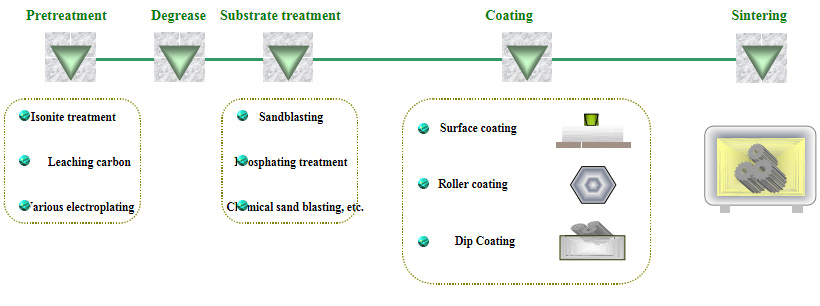

The process is a general example, and can also adopt the design of other process combination.

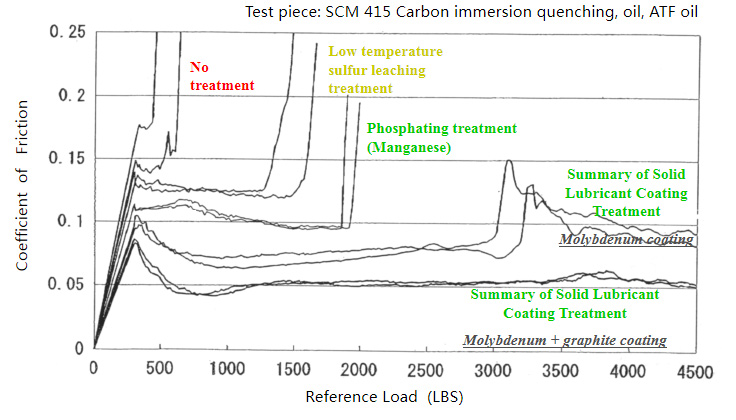

In oil lubrication, solid lubricant coating will play an excellent performance.

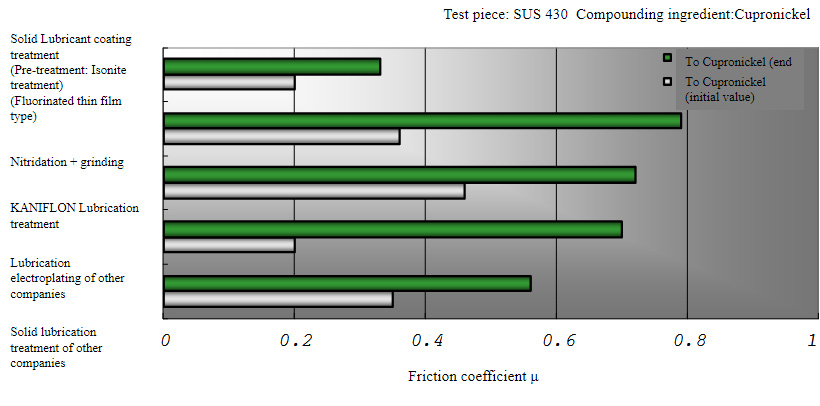

In the results of the actual machine promotion test carried out by the coin separator, the data of the actual machine test after continuous sliding for 1,000 hours are obtained.

◎:No abnormality し ○:Generate less than 1% of red rust ◇:Generate about 1~10% of red rust

△:Generate about 10~30% of red rust ▲:Generate above 50% of red rust

×:Generate about 30~50% of red rust

Corrosion resistance varies according to the type of adhesive used for solid lubricant coatings.